Hydraulic machine, with two cylinders for pressing, one cylinder for cutting and one for rounding. Control panel that allows adjustment of pressing, rounding and shaping chamber opening times. Knife cleaning button. Can store up to 9 different programs

MACHINE CARE

To allow the machine to operate correctly and above all to ensure a long service life, we recommend regular cleaning, both inside and out (see operation manual, chapter/ paragraph on cleaning). The stainless steel parts, painted coatings, PE500 polyethylene and PETG plates can be cleaned simply using water and soap or a neutral detergent, then rinsed thoroughly and dried with a soft cloth.

MATERIALS USED

Frame in electro-welded, painted steel;

Coating in painted steel or stainless steel.

Basins in anticorodal aluminium MG5 with anodising;

Knives and grids in stainless steel 304;

Inner cover surface and presses in polyethylene for foodstuff use PE500;

Plates in polyethylene for foodstuff use PETG;

Ring in aluminium with chemical nickel-plating.

ELECTRICAL POWER SUPPLY

All machines are provided standard for an operating voltage of 400 Volt 50 Hz 3-phase. Other voltages can be provided on request.

All machines are in conformity with EC regulations and are manufactured in Italy.

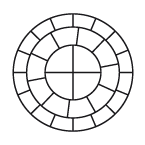

| divisions | min weight gr | max weight gr | basin capacity kg | head diameter mm | hourly capacity pz/h |

|---|---|---|---|---|---|

| 11 | 180 | 500 | 5.5 | 400 | 1300 |

| 15 | 150 | 360 | 5.5 | 400 | 1800 |

| 18 | 120 | 280 | 5 | 400 | 2100 |

| 22 | 60 | 220 | 5 | 400 | 2600 |

| 30 | 40 | 135 | 4 | 400 | 3600 |

| 36 | 34 | 110 | 4 | 400 | 4300 |

| 30s | 25 | 90 | 2.7 | 340 | 3600 |

| 52 | 12 | 30 | 1.6 | 340 | 6200 |